Process and Cost Analysis of Stainless Steel

Release time:

2022-02-13

In 1916, the "father of stainless steel" Brailley invented stainless steel and put it into use. Because of its corrosion resistance, heat resistance, good processability and low price, it is widely used in various fields such as life, household, medical and automobile. Next, let's take these questions, this article from what is stainless steel, stainless steel is how to process, stainless steel cost analysis and stainless steel price trend to explore the world of stainless steel.

In 1916, the "father of stainless steel" Brailley invented stainless steel and put it into use. Because of its corrosion resistance, heat resistance, good processability and low price, it is widely used in various fields such as life, household, medical and automobile. That stainless steel in the end is how to process, its cost and what about it? Next, let us take these questions, to explore the world of stainless steel.

01. What is stainless steel?

stainless steel accordingGB/T20878-2007 is defined as stainless steel, corrosion resistance as the main characteristics, and chromium content of at least 10.5%, the maximum carbon content of not more than 1.2% of the steel. Chromium is also the main alloying element for stainless steel rust prevention. It will form a dense oxide film on the surface of stainless steel to resist external corrosion.

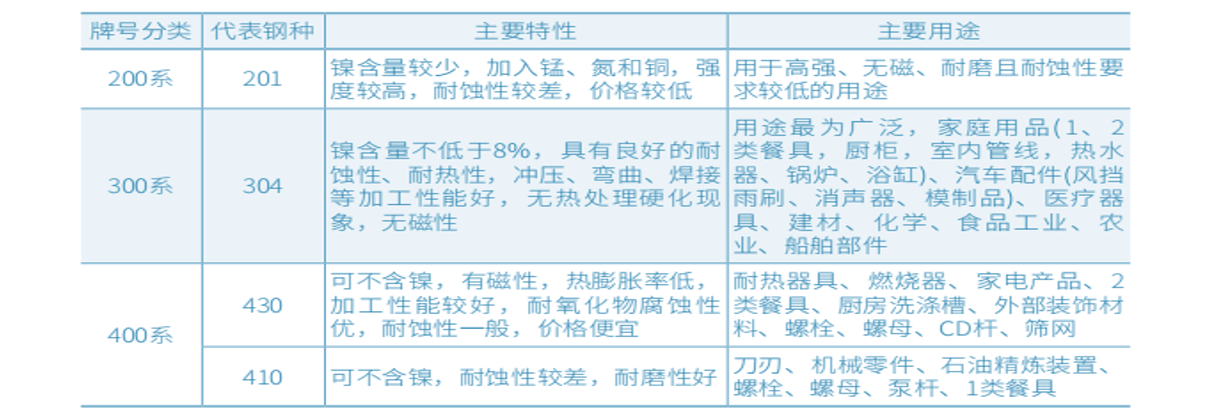

No.Rust steel is often divided into according to the organizational state:Martensitic steel, ferritic steel, austenitic steel, austenitic steel-Ferritic (duplex) stainless steel and precipitation hardening stainless steel.In addition, it can be divided into: chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel. American Iron and Steel InstituteThe 200 and 300 series are marked with austenitic stainless steel, the 430 and 446 series are marked with ferritic stainless steel, and the 410, 420 and 440 series are marked with martensitic stainless steel, which is our commonly used grade classification.

Which chrome nickel stainless steel(300 series) has excellent comprehensive performance and is widely used. Among them, the output of 304 stainless steel represents more than 80% of the output of 300 series, and the market size is 150 billion billion yuan.

02.How is stainless steel processed?

According to the time sequence of smelting process development, it is one-step method, two-step method, three-step method and integrated production process. One-step method: the electric arc furnace completes the process of melting, decarburizing, reducing and refining scrap steel, and directly from the burden to the stainless steel. The two-step method is mainly to use the electric arc furnace as the primary furnace to melt scrap and alloy materials, produce stainless steel primary steelmaking water, and then refine into qualified stainless steel molten steel in different refining furnaces. divided into electric arc furnaceAtmospheric pressure refining furnace and electric arc furnace vacuum refining furnace. (Currently the main method used)Three-step method: primary furnace (electric arc furnace)Atmospheric refining furnace Vacuum blowing oxygen refining furnace. Integrated production: the laterite nickel ore is dried and dehydrated in a rotary kiln, pre-reduced, and then fed into an electric furnace, a rotary kiln submerged arc furnace atmospheric refining furnace for casting and rolling.

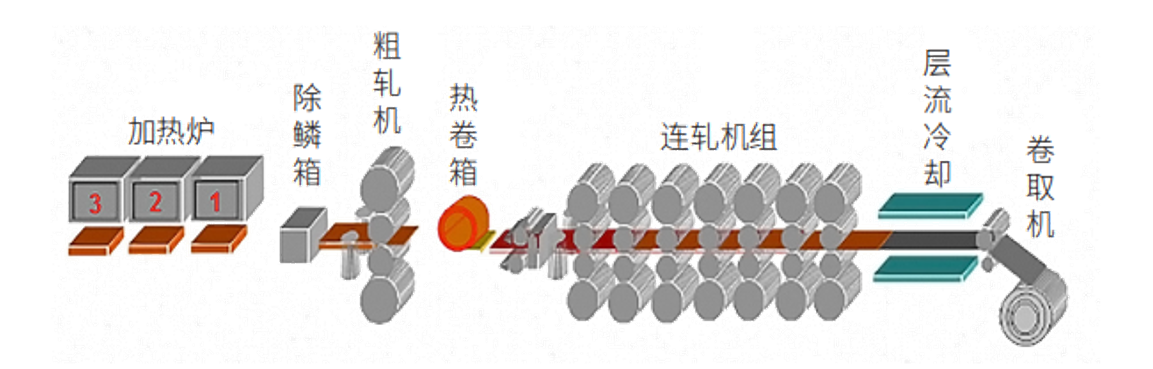

The rolling process is divided into hot rolling and cold rolling. Hot Rolling: Slab(mainly continuous casting billet) as raw material, after heating by rough rolling, finishing mill made of strip steel. After stainless steel hot rolling, a part of stainless steel hot-rolled products are directly used downstream, and another part of hot-rolled products need to be processed into cold-rolled products before use. Cold rolling: on the basis of hot rolled coil rolling processing, is hot rolling → cold rolling → annealing → pickling process. Stainless steel hot-rolled products with a thickness of 3.0 mm-5.5mm are used to produce stainless steel cold-rolled products after rolling processing by cold-rolled equipment. After the stainless steel is cold-rolled, it needs to go through annealing and pickling units respectively. The annealing of stainless steel after cold rolling is to eliminate the work hardening and achieve the purpose of softening through the process of recrystallization. Pickling is to remove the surface oxide layer formed during the annealing process, and to passivate the stainless steel surface to improve the corrosion resistance of the steel plate.

03.Cost Analysis of Stainless Steel

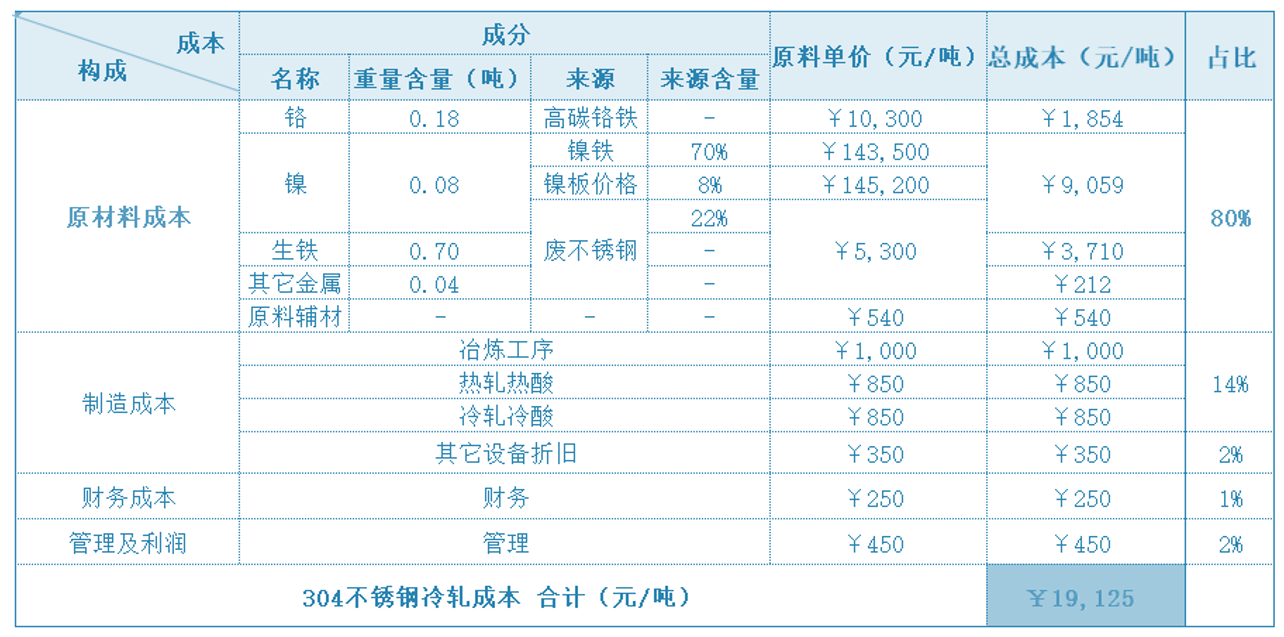

We can divide the cost of stainless steel into four categories: raw material cost, manufacturing cost, financial cost and management and profit cost. B/c304 stainless steel is widely used, we will take a process less cold-rolled stainless steel products as an example for analysis;

It can be seen that the cost of raw material nickel is almost half of the total cost, which students should have a clear understanding.When looking at price movements below, nickel becomes a key factor.

04.Price Trend of Stainless Steel

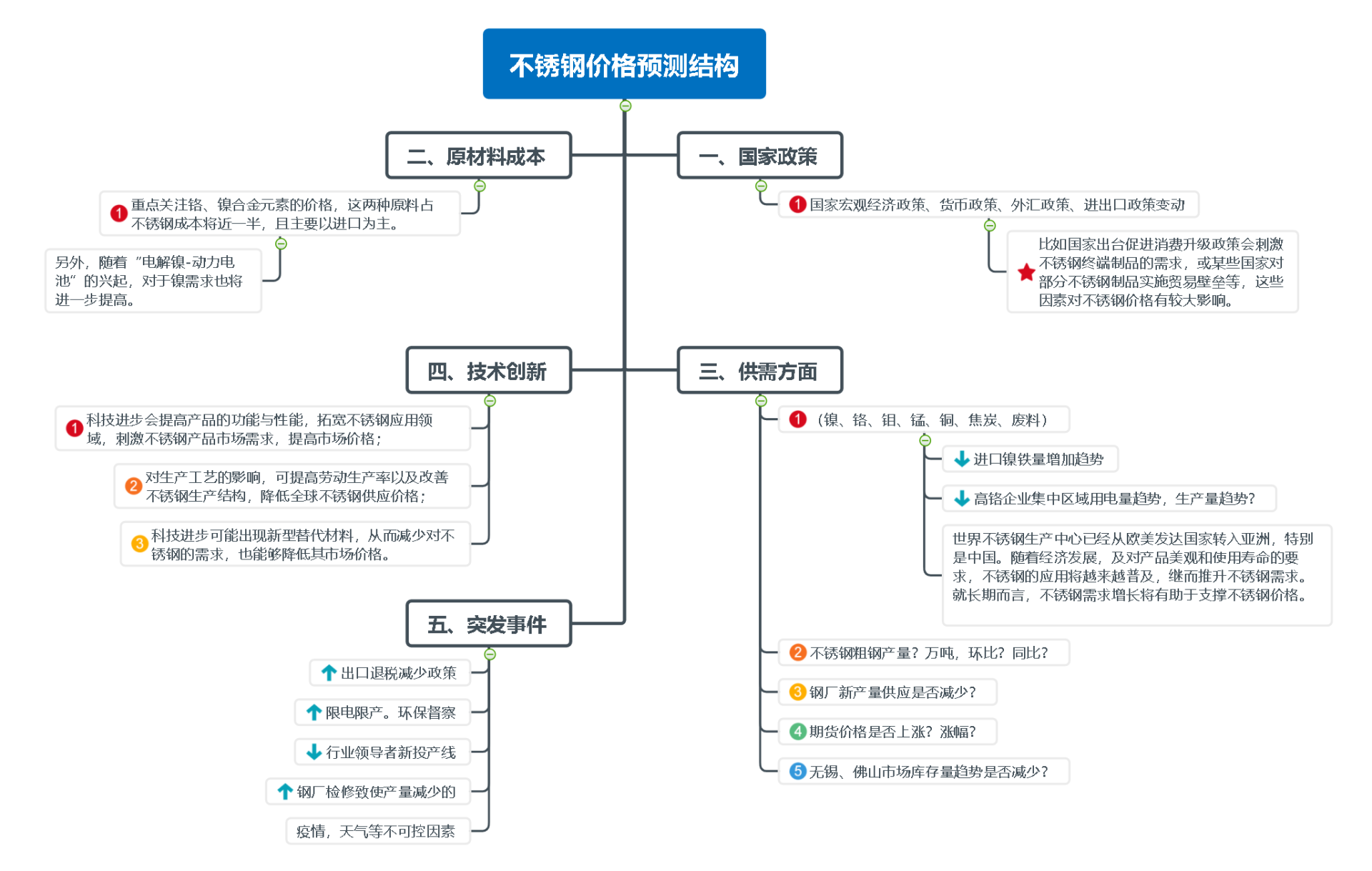

Predicting the price trend of stainless steel can be derived from the followingStart with 5 aspects:

1.National policy: national macroeconomic policy, monetary policy, foreign exchange policy, import and export policy changes, such as the introduction of national policies to promote consumption upgrading will stimulate the demand for stainless steel end products, or some countries to implement trade barriers on some stainless steel products, these factors have a greater impact on stainless steel prices.

2.Cost of raw materials: Focus on the price of chromium and nickel alloy elements, which account for nearly half of the cost of stainless steel and are mainly imported. In addition,The rise of "electrolytic nickel-power battery" will further increase the demand for nickel.

3.Market supply and demand: the world stainless steel production center has been transferred from Europe and the United States developed countries to Asia, especially China. With the development of economy, and the requirements of product beauty and service life, the application of stainless steel will become more and more popular, and then push up the demand for stainless steel. In the long run, the increase in demand for stainless steel will help support the price of stainless steel.

4. Technological innovation: the impact of technological innovation on the stainless steel market: first, scientific and technological progress will improve the function and performance of products, broaden the application field of stainless steel, stimulate the market demand of stainless steel products and increase the market price; second, the impact on the production process can improve labor productivity, improve the stainless steel production structure and reduce the global stainless steel supply price; third, new alternative materials may appear in the progress of science and technology, this reduces the demand for stainless steel and reduces its market price.

5. Emergencies: epidemics, weather and other uncontrollable external causes.

More news